Case study

Engineering for high-end EV charging station

At WILVO Group, we believe that engineering and design go hand in hand in creating future-proof innovative solutions. When EVBox, leader in electric vehicle (EV) charging solutions, asked us to develop a new charging station specifically for the U.S. market, we saw a great opportunity to bring together forward-thinking design, efficient engineering and scalable manufacturing. In collaboration with Van Berlo, a leading design firm with a visionary approach, we developed a charging station that meets the unique requirements of the U.S. market while being easily produced on a large scale.

Read more

Approach

A cost-effective design

The design of the charging station was a major focus of the project. Van Berlo's design team worked closely with us to create a sleek, and modern charging station that appeals to American consumers and is suitable for a variety of environments; from urban landscapes to busy commercial locations and remote areas.

At the same time, our focus was on ensuring a cost-effective design, for broad implementation across the country. Van Berlo's team provided valuable insights on the user experience, ensuring the charging station featured intuitive interfaces, clear LED indicators and a smooth charging process for drivers. The modular design makes installation and maintenance easier. The construction is extremely durable and suitable for wide variations in climate. From cold winters in the Northeast to the hot and dry climate of the Southwest.

Final design

Scalable in-house production

After the design was completed by Van Berlo, our engineering team took the lead in ensuring that the charging station could be produced efficiently, cost-effectively and on a large scale. Given the size of the U.S. market and the speed of EV adoption there, production capabilities had to be optimized from day one. Working closely with Van Berlo's design team, we focused on a streamlined and automated production process. By selecting the right materials and components, we ensured that the charging stations could be produced in high volume, without compromising on quality or performance. Modular components were introduced for faster assembly and easier shipping. This allowed us to shorten/reduce lead times and logistics costs.

Prototyping

Testing in the prototype phase

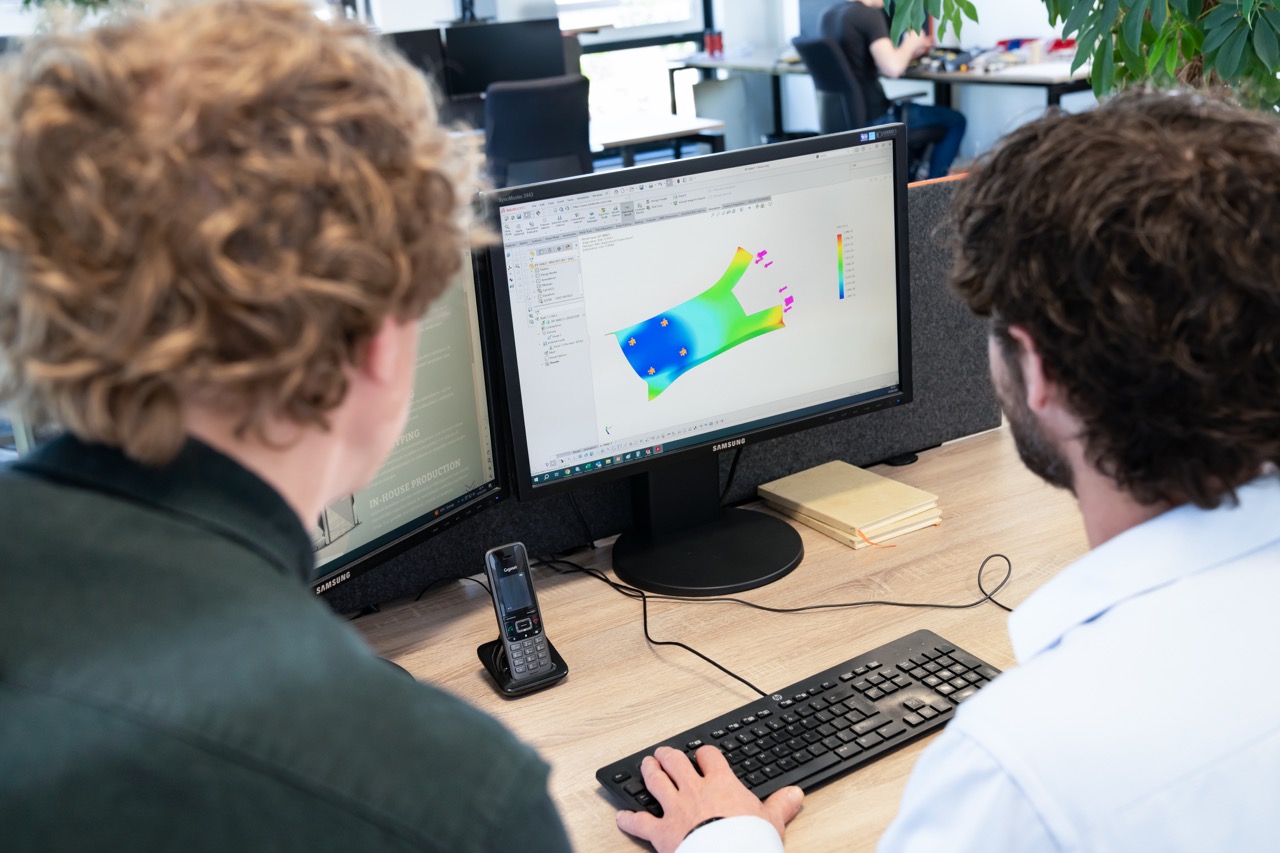

With the final design, the prototyping phase began. Our team built several prototypes that were intensively tested in climate chambers. The testing phase also focused on user safety, ease of use and operational efficiency. We tested the stations' capacity for frequent use, high charging speeds and integration with the growing network of EVs on the road. In addition, we performed simulations to ensure that the stations are easy to maintain and service (for low total cost of ownership for operators).

Read more

Product launch

Scalable and efficient production model

After completing testing and processing feedback, we scaled up production for a nationwide rollout. By implementing automated assembly lines and refining the logistics chain, we ensured EVBox could meet the growing demand for charging stations in the U.S. market without delays or interruptions. Our technical expertise helped optimize the entire production flow; from sourcing high-quality materials to final assembly. With streamlined processes, EVBox was able to quickly deploy the charging stations in cities and along highways, allowing the charging infrastructure to keep pace with the increasing number of EVs on the road.

Read more

Result

Groundbreaking solution and result with impact

The collaboration between The HUB Development, Van Berlo and EVBox resulted in the successful development and launch of a high-performance charging station designed specifically for the U.S. market. These stations provide fast, reliable and scalable solutions essential to supporting the growth of electric driving across the country. With their sleek, modern design and robust engineering, these charging stations are not only easy to install and maintain, but also capable of meeting the diverse needs of U.S. EV drivers. Whether they are located in densely populated urban areas or along rural highways, the stations are an important part of the infrastructure that supports the transition to a cleaner, more sustainable future.

At WILVO Group, we are proud of the role we played in this groundbreaking project. By combining our technical expertise with Van Berlo's design innovation and EVBox's commitment to sustainability, we have brought to life a product that not only changes the way people charge their electric vehicles, but also contributes to a greener future.

Contact Sales

Contact us today and find out how WILVO Group can also be your high-tech partner in cost-efficient production of parts & assemblies and transport solutions in high-mix & low-volume. Do you have a challenge for us? The bigger, the better! Let us think, make and organize. We promise this will make you successful. Our sales team is ready to discuss your specific needs and come up with the best solution together. Together we achieve more.